A £250,000 investment in new presses and robots is proving to be a perfect ‘big’ birthday present for a leading plastic injection moulding and toolmaking specialist.

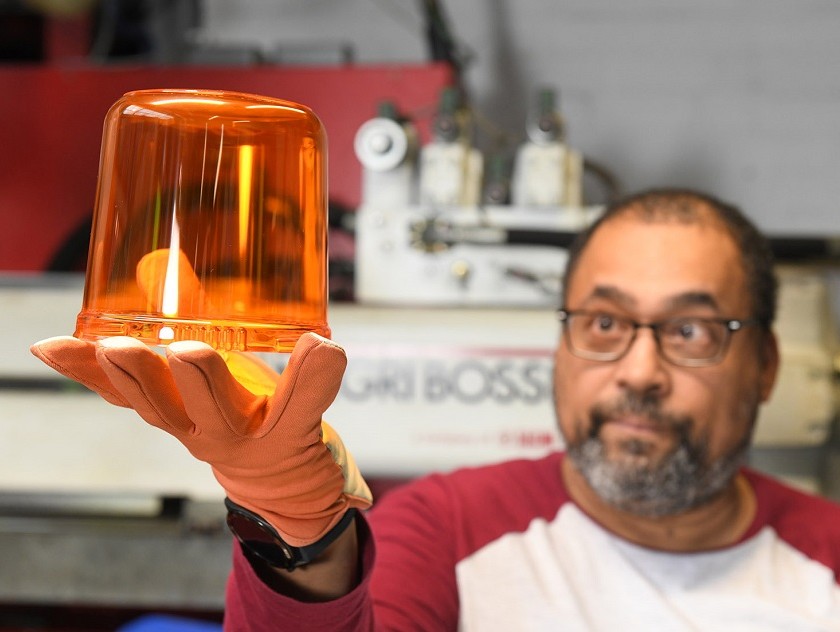

Barkley Plastics, which employs 120 people at its Highgate facility in Birmingham, is celebrating 55 years of business by increasing its capacity to help take on new orders it has won in interior parts and lighting for the automotive sector.

The latest installation takes its total capital machinery spend to over £800,000 in the last five years and highlights the firm’s desire to move into more cosmetic and technical products that require industry-leading processing accuracy.

It marks another step-change in what has been a colourful history for the manufacturer, who started life after founder John Barkley placed a job advert for four toolmakers in the Birmingham Evening Mail.

In the 55 years that followed, the company has evolved its offer to remain a strategic supplier to the automotive sector, whilst also building a strong reputation in the domestic products, construction, electrical and leisure sectors, not to mention producing 20,000 plastic baubles for the world’s largest chandelier - used at the Winter Olympics in Sochi.

“Things have never been quiet over the last 55 years, but I suppose that’s UK manufacturing for you,” said Mark Harwood, managing director at Barkley Plastics.

“We’ve already tried to stay one step ahead of what the customer wants and this is reflected in the latest process that gives us additional capacity and production control to take on more automotive work. There will also be news of a groundbreaking development in injection moulding before the end of the year.

“The £250,000 investment is a perfect birthday present for us and will immediately be put to use on supporting a new project that will see us manufacture a selection of small, high volume JLR parts that will go across its range of vehicles.

“There’s no getting away from the fact that the capital spend is vital, but our people continue to be crucial to our ongoing success. We’ve got more than ten people who have been with us for forty years and David Challinor, the son of one of the founding members, only retired from the toolroom at the end of the year having given us 48 years of service.”

Barkley Plastics, which is IATF16949 accredited, has one of the largest toolmaking facilities in the UK, producing high precision tools capable of delivering 50 million mouldings for distribution throughout the UK, Europe and across the world.

It can support its expanding client base with initial design and product development, right through to manufacture and assembly, with over 40 modern moulding presses – ranging from 5 to 650 tonne – able to produce the most intricate of components.

This is evident in the creation of a dedicated interior lighting assembly cell to mainly support a new project for the Nissan Juke, which has now gone into full production.

Technical director Pete Tedd, who will take over as MD when Mark moves to the position of chairman in April, said: “The increasing range of new electric and hybrid vehicles presents some exciting opportunities that suit our expertise, whilst work is being undertaken to increase our share of the construction, electronics, medical and retail sectors.

“We’re predominantly a sub-contractor, but over the last few years have been looking to develop our own range of products, such as the Plasfloor floor tiles and an anti-static ESD option.

“This is an exciting year for Barkley Plastics and I’m looking forward to moving into the MD role next month. Succession planning is a priority for the business and we have been working hard to develop our senior management team, which will culminate in a number of new directors being appointed in October to support our ambitious growth plans.”

Barkley Plastics is a founder member of the Manufacturing Assembly Network (MAN), a ten-strong collective of sub-contract manufacturers and a specialist engineering design agency.

Apprentice power helps secure new business opportunities

Midlands precision stamping specialists will play significant role

MTC joins forces with Lloyds Bank to help manufacturers

Executive search firm launches new offices in Singapore and Dallas

Company chosen as preferred developer

Industrial coating specialist appoints new lead

Survey reveals sales and production volumes set to fall

Quality management experts add another Far East supplier

Merger brings regional brands together to create network

Iconic motorcycle brand moves to Solihull

New aerospace contracts help firm bounce back from pandemic

Firm uses lessons learned in lockdown to grow further

Vehicle safety specialists secure private equity backing

Associate director strengthens regional team

New partnership organisation will showcase cutting-edge approach